Metal Wall Panels

Metal architecture is all around us: it’s used to make roofs, gutter systems and is growing in popularity for wall applications in commercial and residential buildings. Whether you work in the metal construction industry, are deciding whether to use metal wall panels in your home or business, or just looking for research material, it’s important to familiarize yourself with the basics of metal wall panels before you make any final decisions or purchases.

ALTA TECH Machinery has been the leader in portable roof and wall panel roll forming machinery, and we realize the importance of understanding what exactly you’re working with, how it works, and what it’s used for before you accept a bid on a job, or make any buying decisions.

Uses of Metal Wall Panels

One of the more popular metals used in commercial construction is steel, but wall panels can be made from a variety of materials, including:

| Aluminum | Copper | Stainless steel |

| Steel | Titanium | Zinc |

Types of Metal Wall Panels

Although there are numerous kinds of materials with which you can make metal wall panels, there are three common types of panels used in metal construction. Each one has unique properties, depending on the kind of structure you’re building or the kind of environment surrounding it.

Here is a brief overview of each type of metal wall panel: single skin, metal composite material, and insulated.

Single Skin Metal Panels

Single skin metal panels are also referred to as preformed or roll formed panels. They typically are just a single interlocking layer of prefinished or natural metal that has been roll formed or preformed into the desired profile. Most wall panels of this type can be installed horizontally or vertically in less time and with less of the cost of other metal panel systems.

They can come insulated or uninsulated, and can be made with protective coatings that help fight corrosion and fading. However, since they are less rigid than other types of metal wall panels, they are still very susceptible to damage, especially at ground level. There are certain benefits to using single skin metal wall panels including:

| Lightweight and easy to install | 100% recyclable | Can be installed in almost any weather condition and environment |

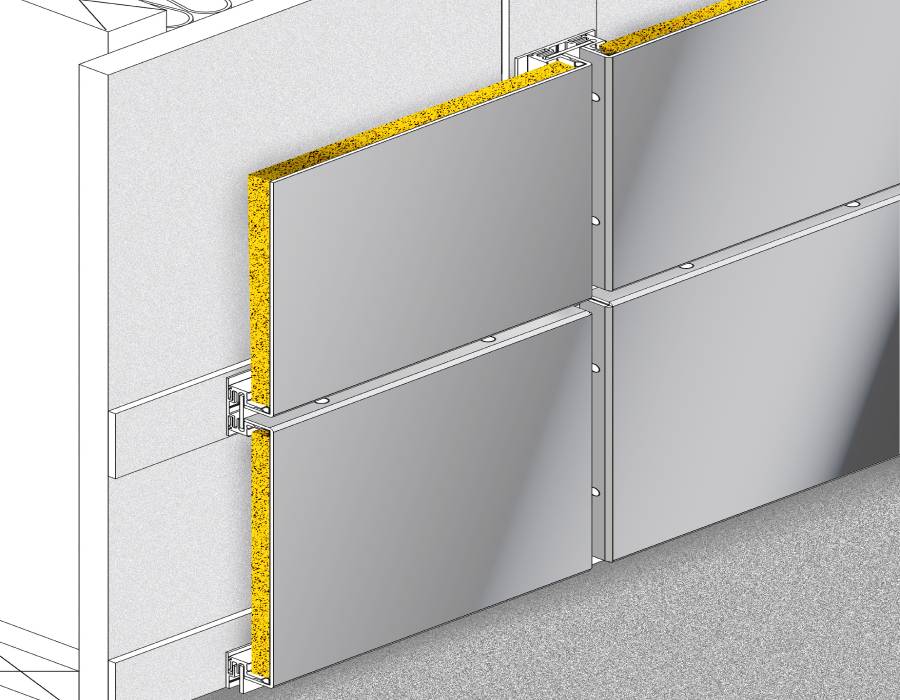

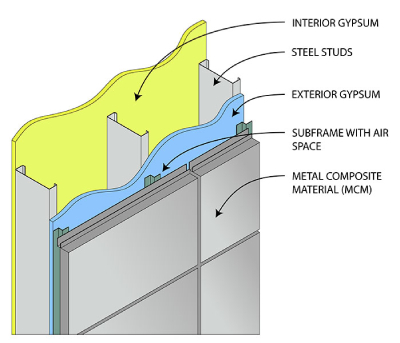

Metal Composite Material (MCM) Metal Panels

This type of metal wall panel has been used in construction projects in North America for almost 40 years.

This type of metal wall panel has been used in construction projects in North America for almost 40 years.

These panels are formed by joining two thick metal skins (predominantly aluminum but can be made of steel, zinc, copper, stainless steel or titanium) to a core that is made of polyethylene or other fire-retardant plastic material, and bonded under a specific temperature, pressure, and tension.

The end product is a metal/plastic composite with greater benefits than just using a solid metal panel of the same thickness.

Advantages of using an MCM panel

| You won’t have oil canning in the panels since the metal skins are bonded to a core, making for a more balanced panel |

| Panels retain their manufactured shape even after installation |

| MCM panels are multi-functional and can be installed on various building types or to join areas between other building materials |

| They retain their beauty and shine for years, and keeps the building’s curb appeal |

| They can be bent, curved, or joined in different shapes depending on what the construction plans require |

| They provide a ‘building envelope’ protecting the exterior of the building against harsh elements, air, and water infiltration |

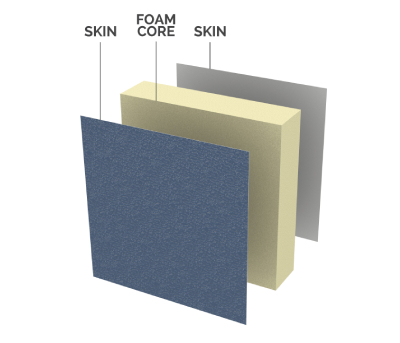

Insulated Metal Panels

As the name suggests, this metal wall panel is made with an insulating foam center (typically expanded polystyrene or polyisocyanurate) sandwiched by two aluminum or steel metal face panels. They make an excellent choice for commercial or industrial buildings and climate-controlled facilities.

As the name suggests, this metal wall panel is made with an insulating foam center (typically expanded polystyrene or polyisocyanurate) sandwiched by two aluminum or steel metal face panels. They make an excellent choice for commercial or industrial buildings and climate-controlled facilities.

When deciding whether or not you should use IMPs for your job, environmental factors should be taken into consideration, as these metal panels need to be sealed properly to prevent water intrusion. Climate also plays a deciding factor, so take into consideration the humidity, temperature, and air movement of the location you plan to install these metal wall panels.

| They come in numerous colors, widths, profiles, and finishes so you can achieve almost any look you desire |

| They provide superior energy-efficient insulation |

| They are quick to install |

Advantages of Using Metal Wall Panels

Why would someone want to use metal wall panels instead of other common materials such as vinyl, brick, stone, or wood? Here are some of the benefits for using metal wall panels over other types, and why they might be better than using traditional wall systems:

Visually appealing: Metal wall panels have beautiful appearances for both interior and exterior applications on commercial or residential buildings. They come in a wide variety of colors, have shiny or matte finishes, and can be shaped and formed into different patterns. The diverse nature of metal wall panels makes them extremely easy for architects and interior designers to use in their projects.

Durability: Structures made from metal materials hold up well under normal wear and tear, so it’s no surprise that metal wall panels would do the same. They don’t dent or ding easily, compared to vinyl panels or wood, and can stay beautiful for years. Most metal wall panels also require minimal maintenance after installation.

Lower costs on installation and maintenance: If you’re looking to purchase metal wall panels for your home, business, or contracted project, you might be happy to know that they have relatively low installation and maintenance costs. Because they are more lightweight than other heavier materials like brick or granite, they can be installed quicker and don’t require as much support structure.

Fireproof and Rain Screen: When building or designing exterior walls, you’ll need to worry about the elements and how they could affect the materials you are working with. Metal walls can act as barriers to fire, helping to prevent spreading and keeping other areas cool if a fire should occur. They also keep water from getting inside of the building, preventing mold or decay from destroying the structure’s integrity.

Environmentally and eco-friendly – Metal walls are considered to be eco-friendly and sustainable materials to use in building construction. They can also help with reducing energy consumption. Another advantage of using metal is that it can be recycled, and still keep its physical properties.

METAL SIDING PANEL SYSTEMS

Metalsiding is an increasingly popular option for residential and commercial buildings due to the variety of ways it can be used, the ease of installation and the longevity of the product. The variety of steel siding panel has helped drive this trend, matched with metal’s longevity and minimal maintenance. When used as siding, metal panels can achieve modern, traditional and even industrial-style designs.

Metal Sidings

| Corrugated Metal Siding | Vertical Siding Panels | Horizontal Siding Options | Modern Exterior Siding |

| Rustic Steel Siding Options | Copper Siding Panels | Rusted Siding Panels |

Siding & Wall Systems for a Modern Look When put into the hands of creative builders, homeowners and architects, any panel can add to a modern design. Metal siding has been uniquely installed on builds to create beautiful, bold lines as siding panel.

Modern Interior Accent Walls, Ceilings & Liners Sleek, clean lines have become a staple in modern design. Modern metals, such as Galvanized steel, have become popular because of their ability to manipulate natural light to create open, airy spaces.

Custom Fabrications: Creating Unique Lasting Beauty

INTERIOR METAL WALL PANELS & ACCENTS

Industrial Interior Steel Wall Panels: Exposed or Hidden Fasteners, Industrial interior steel panels are perfect for garages, shops, warehouses, manufacturing facilities, and other commercial buildings looking for interior siding materials that are long-lasting and durable. With a wide variety of colors and finishes to choose from for your industrial interior metal panels, you can easily create the look you’ve always wanted. These interior siding panels will last for decades.

Flat Interior Steel Metal Wall Covering Panels: Exposed or Hidden Fasteners As with exterior walls, flat metal wall panels are becoming increasingly popular in interior applications. With long, sleek lines, or smooth, squared-off panels, flat wall panel systems work perfectly with modern and contemporary builds. Flat metal wall panels can help you create stunning interior looks. From full accent metal walls to metal wainscoting, these panels can help you create an effortless, aesthetically pleasing look.

Interior Corrugated Metal Panels: Exposed Fasteners Interior corrugated panels fit right into your home, whether you’re using them as metal wall panels or simple accent pieces. A popular option includes using interior metal panels as a kitchen island in rustically designed homes or creating an accent metal wall. The possibilities are endless with interior corrugated metal wall panels! The classic look of steel metal wall covering will complement any home’s interior.

Final Thoughts

While metal wall panels are growing in popularity in all types of buildings, there is a lot that goes into their design and application. We hope that this gives you a better idea how metal wall panels are used, why they might be a better option to use in certain situations over traditional materials, and which type might best suit your needs. At ALTA-TECH Machinery, we believe that education is the key to happy customers, so we strive to make sure we provide you with as many answers as we can to your numerous questions and concerns.